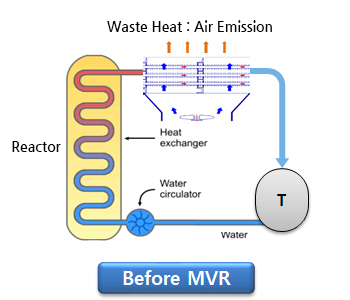

MVR(Mechanical Vapor Recompression) SYSTEM

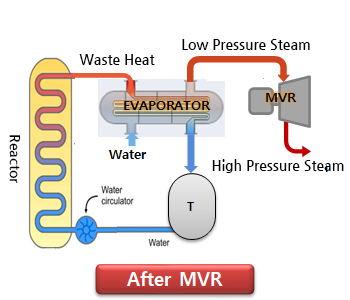

It is a mechanical steam recompression system that maximizes energy recovery by using low-pressure steam or waste low-pressure steam generated by exchanging low-temperature waste heat generated in the production process with an evaporator to the pressure required for the process through MVR.

MVR SYSTEM Basic Configuration

① Evaporator: A device that makes steam by contacting waste heat (evaporation latent heat) generated in the reactor with water.

② MVR (Compressor): A device that boosts the low pressure steam from the evaporator to the required pressure in the process.

- Application criteria

Temperature : Waste heat or hot water above 67 ℃

Steam Pressure Inlet : -0.73 kg / ㎠G min.

Steam Pressure Outlet : 40 kg / ㎠G max

- Compression Ratio : 1.5 ~ 1.8 times / 1 stage

- Benefit

Greenhouse Gas Reduction Effect and Securing

Carbon Emissions through Waste Heat Recovery

Utilizing waste hot water and waste steam as

energy sources for the production Reduction of

production unit cost by energy saving